Challenges in spare parts pricing

Complexity as a challenge

Many companies have considerable portfolios of spare parts, often comprising more than 100,000 items. Processing prices manually without a system support is a Sisyphean task with severely limited prospects of success.

The problem of simplification

To cope with the sheer number of prices, many manufacturers rely on highly simplified pricing procedures. The most common are simple cost-plus methods that differentiate markup rates according to parts groups. Often, a distinction is only made between trade and in-house production parts, as well as the absolute price level. This means that low-cost in-house parts receive the highest markups, while high-cost commercial goods receive the lowest markups.

These rather simple heuristics fall short when competitive pressure increases. Without taking into account the intensity of competition and various challenges in the cost data, such a simple pricing approach often leads to incorrect positioning in the market. Sales declines and margin losses are the immediate consequences.

Excel is not a long-term solution

While Excel is a perfect tool for prototyping and short-term solutions in many contexts, it has natural limitations in the context of professional pricing of spare parts. Multiple pricing logics drive the complexity and thus the potential error-proneness of Excel tools. Also, the sheer number of items in complex pricing methods can lead to performance problems. Another problem is the limited documentation of pricing decisions that often accompanies the use of Excel.

Starting points in spare parts pricing

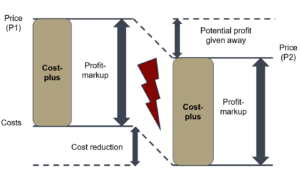

A first improvement approach in spare parts pricing is the extension of existing cost-plus pricing methods. We recommend differentiated cost-plus approaches that also take into account factors such as the intensity of competition or the criticality of spare parts in the context of use. Through a clearly differentiated approach, the market requirements are considered much more precisely.

Value Based Pricing

Often, high purchasing volumes or the use of common parts in series production result in purchasing advantages that are unintentionally passed on to the market as part of cost-plus pricing. One way to avoid this is to introduce value based pricing approaches such as family parts pricing. Here, spare parts prices are not derived from costs but from value from the customer’s point of view.

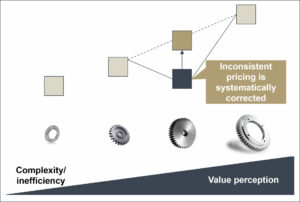

Family Pricing – an example

The example of gears is a good illustration of how family pricing works. From the customer’s point of view, it is easy to understand that a larger gear wheel has a higher price than a smaller gear wheel due to the increased material input.

The price therefore correlates with the size or weight of the gear. Other properties such as the alloy, the number of teeth or the type of gear can be further value drivers. The price is calculated as a formula via the product properties. The costs play no role in this context.

Pricing Software

For spare parts pricing, a multi-method approach is recommended that largely automates the margin potential of the individual parts and examines them from different perspectives. The pricing methods presented above are only a selection from the potential portfolio of methods.

To meet these pricing requirements, professional software for spare parts pricing should be used. With nueprice, we offer a SaaS solution completely focused on the pricing of spare parts, even for large portfolios and the international pricing of parts.

Project experience

Roll & Pastuch has extensive project experience in the field of spare parts pricing:

- Value Based Spare Part Pricing

- Support in the selection process of pricing software

- Introduction Pricing Software nueprice

- International Spare Parts Pricing

- Condition system for spare parts

Start your spare parts pricing project

We will be happy to answer your questions and provide you with further information.

Kai Pastuch

Kai Pastuch ist Geschäftsführer von Prof. Roll & Pastuch. Vor seinem Einstieg als Managing Partner war er als Director bei einer international führenden Strategie und Marketing Beratung tätig. Als Dipl.-Wirtschaftsinformatiker leitet er auch unsere Software Firma nueprice, die sich mit dem gleichnamigen Produkt auf das Pricing von Ersatzteilen spezialisiert hat. Herr Pastuch verfügt über umfangreiche Projektmanagementerfahrung aus zahlreichen Projekten für internationale Großunternehmen und den deutschen Mittelstand in den Bereichen Preismanagement, Marketing, Vertrieb und Strategie. Neben vielfältigen Fachpublikationen in renommierten Zeitschriften und der Herausgabe der Fachbücher Praxishandbuch Preismanagement und Big Deal Management, ist er ein gefragten Moderator und Vortragsredner rund um die Themen Vertrieb und Pricing. Als praxisorientierter Manager engagiert er sich gerne persönlich auf unseren Projekten und bringt in Workshops und Steerings sein breites Erfahrungswissen ein.